Process and Equipment Design

Process Design and engineering information developed with years of experience for project use has become an important strategic asset for us. Thus we provide project execution through best-of-class project delivery & management solutions (e.g., materials & project control) that effectively use engineering information.

With an unparalleled expertise in providing effective & reliable solutions in the process industry (raw sugar plants, white sugar plants, refineries, distilleries, food, energy and power, pharmaceuticals).

The team of highly skilled & committed process engineers is involved in following activities:

- Meticulous designing of energy efficient processes for the process, sugar and allied industries

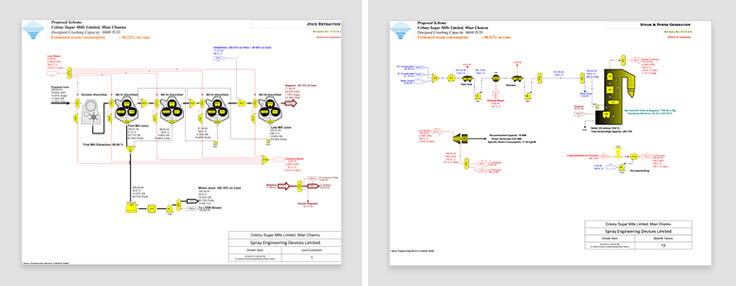

- Mass-Energy balance calculations of the process.

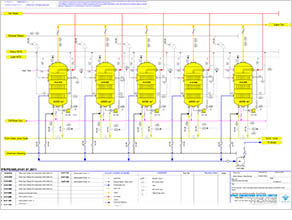

- Preparation of Process & Instrumentation diagrams (P&IDs) and Process Flow diagrams (PFDs).

- Simulation and Optimization using software applications.

- Enthalpy Balance of complete power plant including boilers and power turbine station (Both Extraction and Condensing Turbine)

- Thermal designing calculations of heat exchangers (Radiators, Direct Contact Heaters, Shell and Tube Heat Exchangers, Falling Film Evaporators and Evaporative Condensers etc.)

- Sizing of the Heat Transfer Equipments.

Equipment Design and Engineering with advanced technology, precision tools, and complex mechanical design expertise, our team of engineers provide a complete range of mechanical design services to test, analyze, improve and simplify the most complicated process machinery & equipments. Our unique products / equipments represent quality, efficiency & reliability in the global market. Our Equipment Design & Engineering section forms the core of our detailed engineering involving a range of activities in the product development from concept to detailed design to production drawings like:

- Product design and detailed engineering.

- Product market research and marketing analysis.

- Understanding customer needs, and translating those needs into winning product concepts that have realistic technical specifications.

The engineering tools currently being used by our mechanical design group include softwares / systems for:

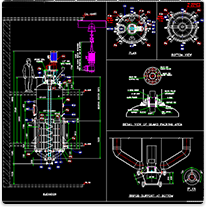

- Complete layout design & detailed drawings of equipments along with BOM;

- Detailed modeling & design of equipments & Piping layout of equipments / process sections of plants;

- Analysis of flow of fluids through components for design optimization;

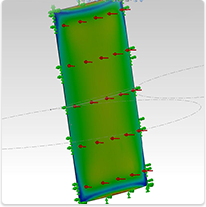

- Mechanical Analysis / Structural Design of components & optimization of components by analyzing Strain Energy Distribution, Stress & Deflection;

- Generate load & velocity curves for checking shock loading of rotary components;

- Design of supporting structure of equipments as per Structure Codes like IS-800;

- Diagrammatic representation of Complete Boiling Process House.